Products

Machinery for the production of candy, toffee, and chocolate for the confectionery and food industry

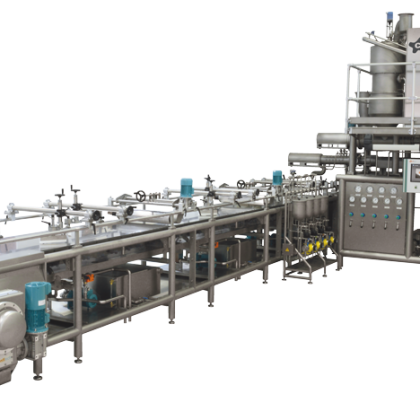

Continuous Cooking Line

CKC family of continuous cookers integrate cooking, aromatization, colouring, addition of acid, mixing and tempering in a single line.

The CKC.75 and CKC.120 can produce up to 750 kg/h (1,650 lbs/hr) or 1.200 kg/h (2,650 lbs/hr) of sugar based or sugar free hard candy.

Combining the advantages of Plate Heat Exchanger technology with a high level of automation Confitech continuous cookers represent an efficient and reliable solution for high capacity production processes.

The cooking process is carried out in a PHE from which the product flows into a flash-off chamber, where it looses its moisture. Just below the flash-off chamber, a vacuum chamber provides extra moisture release, while a screw extracting unit drives the product into a dynamic in-line mixer where colours, flavours and acid are automatically mixed to the mass at pre-set ratios.

The mass is finally collected on a stainless steel cooling band having three independent cooling sections.

Three folding ploughs and rollers provide smooth tempering and kneading of the mass that is then directly fed to the forming machines.

The twin mixer version CKC.100D allows the simultaneous tempering process of two candy different colour and flavour.

Details

Cooking, aromatization, colouring, addition of acid, mixing and tempering integrated in a single machine.

Reliable and efficient solution for high capacity production processes.

Single or multi colour processing.

Capacity from 750 Kg/h (1,650 lbs/hr) up to 1.200 Kg/h (2,650 lbs/hr).

CKC.75

CKC.120