Products

Laminator

€0,00

In stock

Product Details

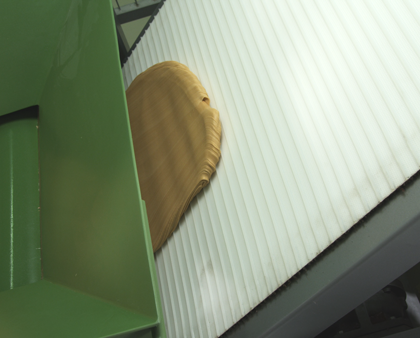

The Sheeter LAM.200 is specifically designed to transform soft candy batch in band of consistent width and thickness and transfer it to the Cooling and Stabilizing conveyors

In case of discontinuous processes, such as those applied to extruded chewy candy that require significant curing time, the LAM.200A features a short inclined belt and a batch cutting unit designed to cut the laminated batches in slabs of pre-set dimensions that can be easily handled and stored to complete crystallization before reaching the extruder.

Details

Lamination and automatic transfer to Cooling / Stabilizing Conveyors.

Lamination and cutting in slabs for further crystallization, when required.

Capacity up to 1.000 kg/h (2,200 lbs/hr)

LAM.200

LAM.200A

Display prices in:

EUR