Products

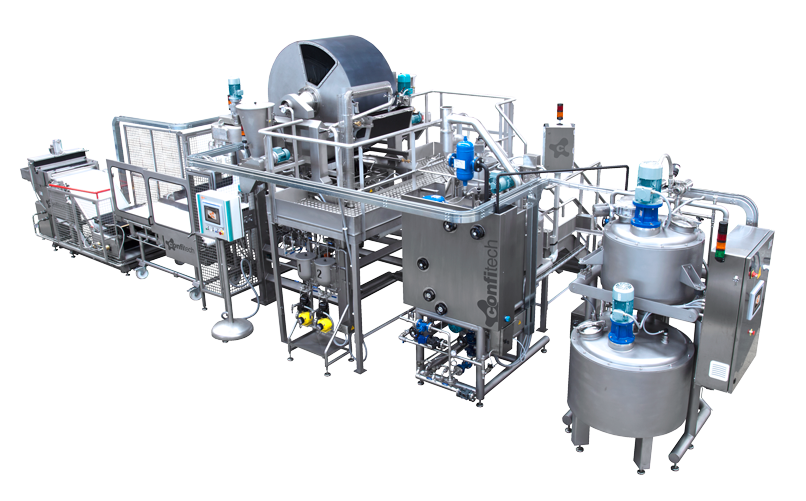

Cooling Drum

Continuous cooling drums, first introduced and patented by our company in 1960s represent the most efficient, compact and labour saving solution for the cooling of all types of low boiled soft candy, chews, caramels and toffee.

Confitech supplies a wide range of models with capacity from 300 to 1.200 kg per hour.

All models feature a water cooled Teflon® coated stainless steel drum with variable speed gear, automatic temperature control and thickness adjusting device.

Smaller models RCT.100 and RCT.150 are operator assisted machines recommended for operations from 300 to 500 kg per hour, where batch transfer is manually executed.

Larger models such as RCT.150T, RCT.800 and RCT.1200, usually integrated in fully automatic processing lines, are equipped with automatic batching system that allows the automatic feeding of one or two pulling machines with batches of pre-set size.

When required, the batching system can be integrated with dry feeders DF.10 designed to dispense granular agents directly into the cooled mass, such as acid, powdered sugar, fondant, crushed nuts or other heat sensitive additives, at preset ratios in a fully automatic way.

Also, aromatization units DP.40 or DP.60 can be linked to the system to allow automatic dosing of liquid flavours and colours, independently for each batch.

Colour and flavour alternation between batches is also possible, thus allowing to run double colour products from the same unit.

Details

Efficient and compact cooling solution.

All stainless steel execution.

Weigh control and batch cutting for automatic transfer to pulling machines.

Automatic addition of liquid and granular additives at pre-set ratios.

Single or double colour process.

Capacity from 300 to 1.200 Kg/h (660 – 2,650 lbs/hr)

RCT.100

RCT.150

RCT.150T

RCT.800

RCT.1200